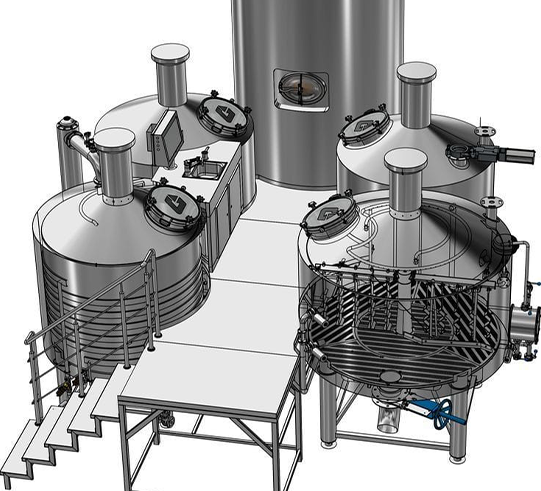

Our range of brewing tanks includes individual fermentation, storage, and brewing tanks, up to complete turnkey plants.

We design production processes and process units in accordance with hygienic standards and ensure the project during the manufacturing phase of plants and installations.