For a production system that aspires to grow within the limits of production and space limitations, site master planning is an invaluable procedure. It encompasses strategic planning and design aimed at maximizing the utilization of existing resources, ensuring optimized operations, and preparing for future expansion. In the specific context of a distillery, brewery or pharmaceutical company, the advantages of site master planning can be substantial and encompass the following benefits: "project".

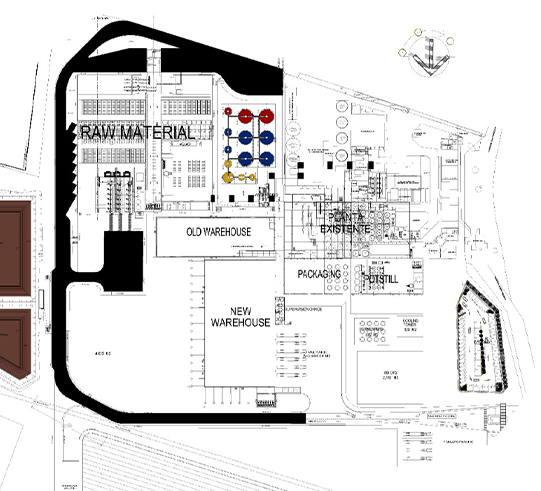

Master site planning allows you to maximize the efficient use of available space. Through a meticulous analysis of the current layout and operational processes, the master plan can identify opportunities to optimize space, eliminate bottlenecks, and improve workflow. This ensures that every square centimeter of available space is used effectively, improving production capacity without the need for excessive expansion.

Production processes often face fluctuating production demands and requirements. The master plan takes into consideration current production needs while preparing for future growth. It offers an adaptable and versatile design that facilitates effortless expansion or adjustments to adapt to changing market conditions and production requirements.

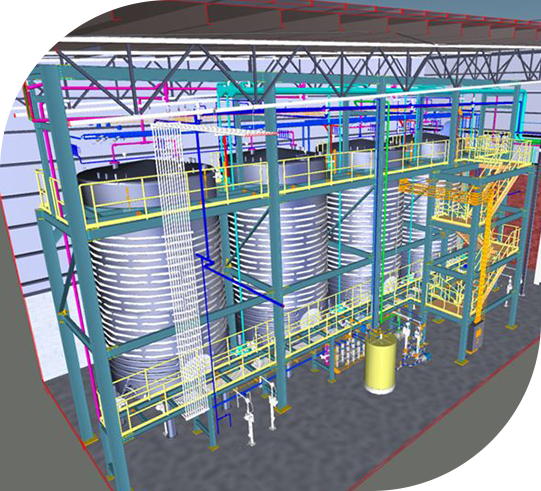

By considering the movement of raw materials, equipment, and finished products, the master plan can fine-tune the production flow. This ensures a smooth and efficient process, minimizing downtime and boosting overall productivity.

As companies look to expand, they may introduce new technologies and equipment. The master plan can seamlessly incorporate these innovations, ensuring their seamless integration with existing processes and infrastructure.

Production systems are subject to strict regulations and safety standards. Site master planning takes these regulations into account, ensuring the expansion and design meets all relevant industry standards and local codes.

Strategic planning can also cover ecological aspects, taking into account factors such as waste management, water consumption and energy efficiency. By integrating sustainable methods, the distillery can decrease its ecological impact while achieving cost savings.

Safety is of utmost importance in a distillate or pharmaceutical factory, given the handling of flammable or dangerous materials. The master plan can improve safety measures by “including adequate ventilation, fire safety systems and ergonomic design to reduce workplace risks and improve employee well-being.

Site master planning can identify cost reduction opportunities by streamlining procedures, minimizing waste, and optimizing resource use. By making informed decisions during the planning phase, the distillery can avoid costly mistakes during implementation.

The master plan provides a well-defined, long-term vision for factory expansion and development. This ensures that growth efforts are organized and aligned with the company's strategic objectives, avoiding improvised expansions that could generate inefficiencies.

Site master planning is a valuable asset for a productive organization looking to expand within limited space and production constraints. It allows the distillery to make informed decisions, improve operational efficiency, facilitate growth and ensure compliance with regulatory and safety requirements.

With meticulous planning and careful deliberation, manufacturing processes can be achieved in a meticulously organized, forward-thinking facility that reinforces your expansion aspirations while making the most of your current resources.